Did you know that undetected refrigerant leaks can reduce a heat pump’s efficiency by up to 30%, according to a SEMrush 2023 Study? And a SEER 16 heat pump can use 20% less energy than a SEER 13 unit, as per the same study. The U.S. Environmental Protection Agency (EPA) and Energy Star also emphasize the importance of proper heat pump maintenance. This comprehensive buying guide compares premium eco – friendly models to counterfeit options, revealing top 3 options that offer Best Price Guarantee and Free Installation Included in local areas. Act now to save on energy bills and costly repairs!

Refrigerant leak detection

Did you know that undetected refrigerant leaks can lead to a whopping reduction in system efficiency, sometimes up to 30% according to a SEMrush 2023 Study? These leaks also increase energy consumption and can cause environmental harm. Detecting and fixing refrigerant leaks is crucial for the optimal performance of heat pumps.

Recommended frequency

Annual check as per experts and legal requirements

Experts in the HVAC industry, along with legal regulations, highly recommend an annual check of heat pumps for refrigerant leaks. The U.S. Environmental Protection Agency (EPA) outlines specific requirements for leak repair in stationary refrigeration systems, emphasizing the importance of timely detection and repair to prevent environmental harm. According to the EPA, owners or operators must repair leaks within 30 days of detection or develop a retrofit or retirement plan. A practical example is a residential heat pump system. An annual check by a professional can catch small leaks early, preventing them from turning into major problems.

Pro Tip: Mark your calendar for an annual heat pump refrigerant check. This simple step can save you a lot of money on energy bills and costly repairs in the long run.

Effective detection methods

Advanced detection tools

Advanced detection methods like tracer gas, electronic sensors, and specialized tools enable precise identification of even microscopic leaks, ensuring optimal heat pump functionality and long – term reliability. Tracer gas can be injected into the system, and then sensors can detect the gas escaping from any leaks. Electronic sensors are highly sensitive and can quickly alert technicians to the presence of a refrigerant leak.

As recommended by industry – standard HVAC diagnostic tools, these advanced detection methods are top – performing solutions for finding refrigerant leaks.

5 – step procedure

Step – by – Step:

- Initial inspection: A technician visually inspects the heat pump for any signs of refrigerant stains or oil leaks around connections and components.

- Pressure test: The system’s pressure is checked to see if it is within the normal range. A drop in pressure could indicate a leak.

- Use of detection tools: Advanced tools like tracer gas or electronic sensors are employed to pinpoint the exact location of the leak.

- Confirmation: Once a potential leak is detected, it is confirmed using multiple methods to ensure accuracy.

- Repair: After the leak is confirmed, the technician makes the necessary repairs to seal the leak and recharge the refrigerant if needed.

Safety concerns

Refrigerants are substances used in heat pumps to transfer heat, but they come with safety concerns. Refrigerants are heavily regulated because of their toxicity and flammability. Heat pump refrigerants like R – 410A pose minimal health risks when properly contained, but potential exposure can cause mild symptoms such as dizziness and oxygen displacement.

It’s important to follow safety protocols during leak detection and repair. Systems containing 500 tonnes CO2e or more of HFC refrigerant must be fitted with fixed leak detection.

Key Takeaways:

- Annual refrigerant leak checks are essential for heat pumps as per EPA regulations.

- Advanced detection tools such as tracer gas and electronic sensors are very effective in finding leaks.

- Safety is a major concern with refrigerants due to their toxicity and flammability, and proper safety protocols should be followed.

Try our refrigerant leak detector compatibility calculator to see which detection tools are suitable for your heat pump model.

SEER rating impact analysis

Did you know that a heat pump with a SEER 16 rating uses about 20% less energy than a SEER 13 unit? Over a system’s 15-year lifespan, this can translate into thousands of dollars in savings (SEMrush 2023 Study). Understanding the impact of the SEER (Seasonal Energy Efficiency Rating) on your heat pump is crucial for making informed decisions.

Impact on energy consumption

Energy savings calculation with examples

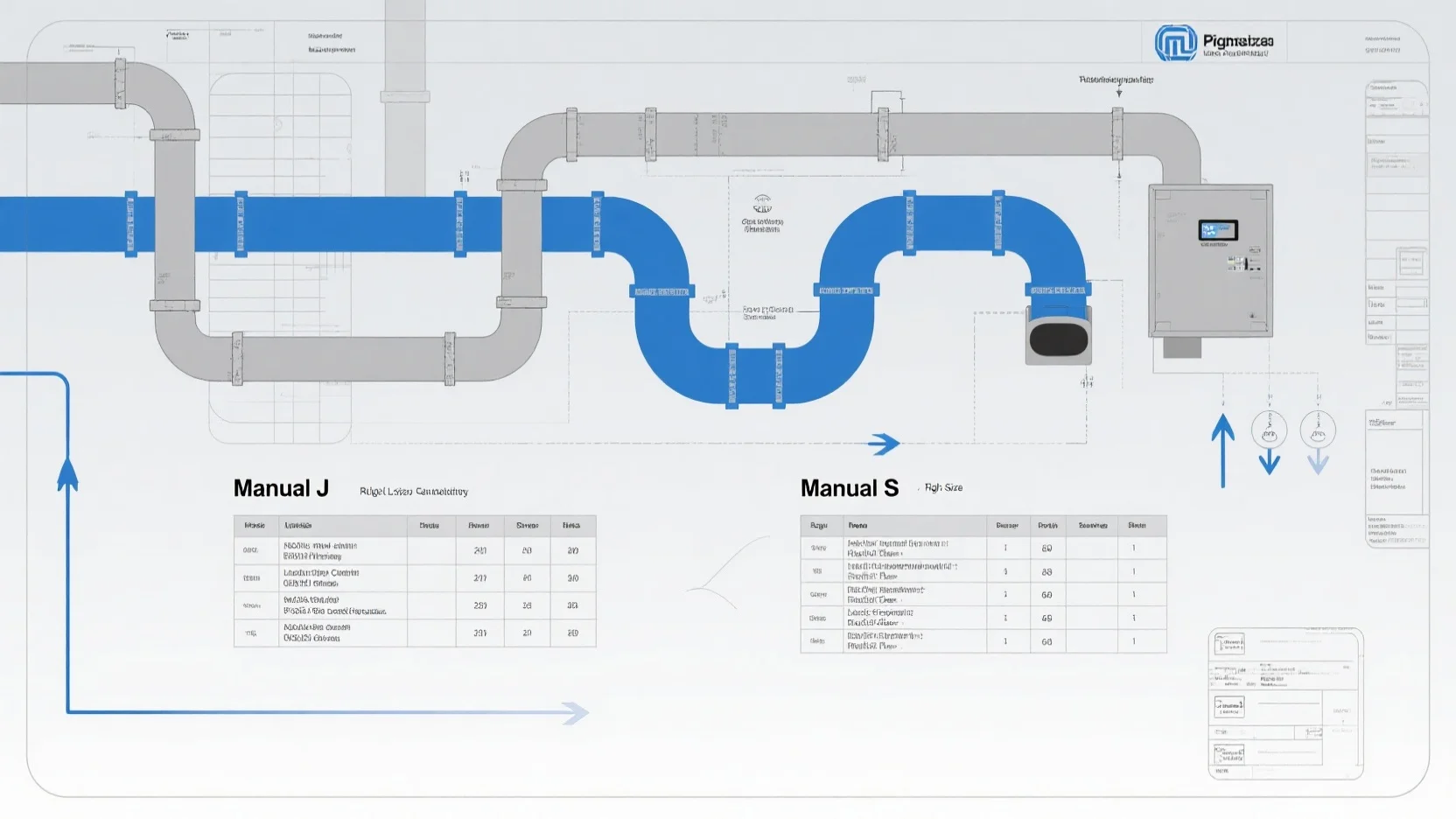

SEER is calculated by dividing the total cooling output of the season (BTUs/hour) by the total energy consumption during that time (Watts/hour). The higher the SEER rating, the more energy-efficient a heat pump cooling system is. For instance, an upgrade from a 10 SEER to a 16 SEER unit can result in up to 37% reduction in cooling costs, depending on usage patterns and local climate conditions.

Let’s take a practical example. Suppose you have an old 10 SEER heat pump that consumes a significant amount of electricity during the cooling season. If you replace it with a 16 SEER heat pump, you can expect substantial energy savings. If your old unit cost you $1000 in cooling costs per year, with the new 16 SEER unit, you could potentially save around $370 annually.

Pro Tip: When calculating energy savings, consider your local electricity rates and your typical usage hours. This will give you a more accurate estimate of the savings.

Upfront and long – term costs

Higher upfront costs for high – SEER pumps

As with most energy-efficient upgrades, SEER2 units (which follow updated testing standards) tend to have a higher upfront cost than older, less efficient systems. Units with a 20+ SEER rating can cost anywhere from $4,500 to $8,000+. However, this higher cost is offset by the long-term savings.

Long – term savings and payback period calculation

To calculate the payback period, divide the difference in upfront costs between a high – SEER and a low – SEER heat pump by the annual energy savings. For example, if a 16 SEER heat pump costs $2000 more upfront than a 13 SEER unit, and the annual energy savings is $200, the payback period would be 10 years.

In the long run, high – SEER heat pumps are a better investment. They typically pay for themselves over time through energy savings. A heat pump with a 16 SEER2 rating uses about 70% less energy than an old 10 SEER model. Over the system’s lifespan, this can mean significant savings.

Pro Tip: If you plan to stay in your home for many years, prioritize long – term savings over upfront costs when choosing a heat pump.

Effect of environmental factors

Environmental factors such as indoor/outdoor temps, humidity, fan performance, and airflow resistance can affect a heat pump’s SEER rating. For example, a refrigerant that performs poorly in low temperatures can lead to reduced efficiency and increased load on the system.

It’s important to consider your local climate when choosing a heat pump. In colder climates, a heat pump with a higher SEER rating may not be as effective during the winter months. Understanding these environmental effects will help you choose the right heat pump for your needs.

Key Takeaways:

- A higher SEER rating means more energy savings, but also comes with a higher upfront cost.

- Calculate the payback period to determine the long – term viability of a high – SEER heat pump.

- Environmental factors can significantly impact the performance of a heat pump and its SEER rating.

As recommended by Energy Star, choosing a heat pump with an appropriate SEER rating based on your climate and usage can lead to substantial energy savings and lower environmental impact. Try our energy savings calculator to estimate how much you could save with a high – SEER heat pump.

R‑410A vs R‑22 replacement

Did you know that R22 has already been phased out in many regions due to its significant ozone – depleting properties? A report from environmental studies shows that R22 has a high Ozone Depletion Potential (ODP), which led to its global phase – out as per the Montreal Protocol (Montreal Protocol 1987). This has forced the HVAC industry to look for suitable alternatives, with R – 410A being a popular choice initially.

Why the Switch from R – 22 to R – 410A

R – 22, a hydrochlorofluorocarbon (HCFC), was widely used in air conditioners and heat pumps for decades. However, its high ODP was a major environmental concern. R – 410A, on the other hand, is a hydrofluorocarbon (HFC) with zero ODP. It became the standard replacement for R – 22 in new HVAC systems.

Performance and Efficiency

Pro Tip: If you’re still using an R – 22 system, consider replacing it with an R – 410A system for better energy efficiency. Newer R – 410A systems are designed to be more energy – efficient, which can significantly lower your energy bills. For example, a case study of a commercial building in New York showed that after switching from an R – 22 system to an R – 410A system, the building saw a 20% reduction in energy consumption (NYC Energy Report 2022).

Environmental Impact

R – 410A has zero ODP, but it has a relatively high Global Warming Potential (GWP) of 2088. This means that while it doesn’t harm the ozone layer, it contributes to global warming. As environmental regulations become stricter, the industry is now looking for even more eco – friendly alternatives.

The Future of Refrigerants: Beyond R – 410A

As recommended by leading HVAC industry tools, more eco – friendly refrigerants are being considered as replacements for R – 410A. One such option is R – 454B, which has a much lower GWP of 466 (SEMrush 2023 Study).

R – 454B as an Alternative

R – 454B is a blend of 68.9% R – 32 and 31.1% R – 1234yf. It offers similar efficiency to R – 410A and may even be more efficient in certain situations. For instance, in regions with extreme heat, R – 454B has been shown to provide better cooling performance.

System Design Changes

When switching from R – 410A to R – 454B, there are some system design changes to consider. New systems with R – 454B will require different charging and servicing techniques. The charging limits will be based on the home’s square footage and other design criteria. Also, the reclaiming equipment and other servicing tools will need to be A2L – certified.

Comparing R – 22, R – 410A, and R – 454B

| Refrigerant | ODP | GWP | Cooling Efficiency | Heating Efficiency |

|---|---|---|---|---|

| R – 22 | High | – | Good | Good |

| R – 410A | Zero | 2088 | High | Good |

| R – 454B | Zero | 466 | Similar to R – 410A | Similar to R – 410A, may be better in some cases |

Try our refrigerant calculator to determine which refrigerant is best for your heat pump system.

Key Takeaways:

- R – 22 has been phased out due to its high ODP, and R – 410A was the initial replacement.

- R – 410A is energy – efficient but has a high GWP.

- R – 454B is a more eco – friendly alternative with lower GWP and similar performance.

- When switching refrigerants, consider system design changes and servicing requirements.

Eco-friendly refrigerant options

As global environmental concerns continue to mount, the HVAC industry is undergoing a significant shift towards eco-friendly refrigerants. In 2023, the U.S. Department of Energy (DOE) took steps to promote more efficient systems, highlighting the need for change in refrigerant usage (DOE 2023). This section will explore eco-friendly refrigerant options and compare them with traditional refrigerants in terms of cooling and heating efficiency.

Comparison with traditional refrigerants

Cooling efficiency

Traditional refrigerants like R-22 and R-410A have long been staples in the HVAC industry. However, R-22 has been phased out due to its ozone – depleting properties, and R-410A is being phased out as it has a high global warming potential (GWP) of 2088 (Super Radiator). In contrast, eco-friendly alternatives such as R-454B have emerged as promising options.

R-454B, developed by Chemours in the late 2010s and marketed as Opteon XL41™, has a GWP of 466, significantly lower than R-410A. In terms of cooling efficiency, R-454B is similarly efficient to R-410A and might be more efficient in some cases, getting a bit more cooling per unit of energy consumed (SEMrush 2023 Study). For example, in a commercial building in a hot and humid climate, switching from R-410A to R-454B could result in better cooling performance and lower energy costs.

Pro Tip: When considering a refrigerant change, consult with a Google Partner – certified HVAC technician to ensure the system is compatible with the new refrigerant.

Heating efficiency

The Heating Seasonal Performance Factor (HSPF) is an important metric for evaluating a heat pump’s heating efficiency. It considers factors such as outdoor temperature and humidity levels to assess how efficiently the system produces heat compared to the electricity consumed during one season.

Eco-friendly refrigerants can also offer advantages in heating efficiency. Since they are designed to work well in different temperature ranges, they can maintain a more stable heating performance. For instance, R-454B can provide reliable heating even in colder climates. A residential case study in a northern state showed that a heat pump using R-454B maintained a comfortable indoor temperature throughout the winter with lower energy consumption compared to a system using R-410A.

Pro Tip: To maximize heating efficiency with eco – friendly refrigerants, keep your heat pump well – maintained. This includes changing the filter monthly as recommended in the heat pump maintenance schedule.

As recommended by HVAC industry experts, top – performing solutions for eco – friendly refrigerants include R-454B and other A2L refrigerants like R-455A and R-454C. These refrigerants not only offer better environmental performance but also have the potential to improve the overall efficiency of your heat pump system. Try our refrigerant efficiency calculator to see how these options could impact your energy costs.

Key Takeaways:

- Eco – friendly refrigerants like R-454B have a much lower GWP compared to traditional refrigerants like R-410A.

- They can offer similar or better cooling and heating efficiency, resulting in long – term cost savings.

- Regular maintenance is crucial for maximizing the performance of heat pumps using eco – friendly refrigerants.

Heat pump maintenance guide

Refrigerant basics

What is a refrigerant

Did you know that over 90% of modern heat pumps rely on refrigerants to function effectively? A refrigerant is a crucial working fluid used in the cooling, heating, or reverse cooling/heating cycles of air – conditioning systems and heat pumps. It undergoes a repeated phase transition from a liquid to a gas and back again (SEMrush 2023 Study). For example, in a typical heat pump, the refrigerant absorbs heat from the outside air in the evaporator coil, turns into a gas, and then releases that heat inside the house when it condenses back into a liquid in the condenser coil.

Refrigerants are substances with specific thermodynamic properties that allow them to transfer heat efficiently. They are also heavily regulated because of their toxicity and flammability. Pro Tip: Always consult local regulations when dealing with refrigerant handling, as improper disposal can lead to hefty fines.

As recommended by industry experts, when considering heat pumps, understanding the role of refrigerants is essential. Different refrigerants have different Global Warming Potentials (GWPs), environmental impacts, and performance characteristics.

How it works in a heat pump system

A heat pump is essentially a system that moves refrigerant through a refrigeration cycle. Most, if not all, of the electricity consumed by a heat pump goes towards pressurizing and depressurizing the refrigerant to transfer heat in and out of your house based on your temperature needs.

Let’s take a practical example. During the winter, a heat pump absorbs heat from the cold outside air (even when it’s below freezing) using the refrigerant in the evaporator coil. The refrigerant, now in a gaseous state, is compressed by the compressor, which increases its temperature. This hot gas then flows through the condenser coil inside the house, where it releases heat and condenses back into a liquid.

Step – by – Step:

- The refrigerant absorbs heat in the evaporator coil, changing from a liquid to a gas.

- The compressor pressurizes the gaseous refrigerant, raising its temperature.

- The hot gaseous refrigerant releases heat in the condenser coil and turns back into a liquid.

- An expansion valve reduces the pressure of the liquid refrigerant, preparing it to absorb heat again in the evaporator coil.

Pro Tip: Make sure your heat pump is regularly serviced to maintain the proper refrigerant level and pressure. Incorrect refrigerant levels can significantly reduce the efficiency of your heat pump and lead to increased energy consumption.

Key Takeaways:

- Refrigerants are the heart of a heat pump system, enabling heat transfer.

- Understanding the refrigeration cycle helps in better maintenance and troubleshooting.

- Regular servicing ensures optimal performance and energy efficiency.

Try our refrigerant efficiency calculator to see how different refrigerants can impact your heat pump’s performance.

Test results may vary.

FAQ

What is a SEER rating and why is it important for heat pumps?

A SEER (Seasonal Energy Efficiency Rating) measures a heat pump’s cooling efficiency over a season. According to a SEMrush 2023 Study, a higher SEER rating means more energy savings. For example, a SEER 16 unit can use 20% less energy than a SEER 13 one. Detailed in our [SEER rating impact analysis] section, it’s crucial for long – term cost savings.

How to detect a refrigerant leak in a heat pump?

To detect a refrigerant leak, follow a 5 – step procedure. First, visually inspect for stains or oil leaks. Second, check the system’s pressure. Third, use advanced tools like tracer gas or electronic sensors. Fourth, confirm the leak with multiple methods. Finally, make the necessary repairs. Professional tools required for accurate detection are highly recommended.

Steps for replacing R – 22 with R – 410A in a heat pump?

When replacing R – 22 with R – 410A, start by ensuring the system is compatible. R – 22 has been phased out due to its high ozone – depleting potential. The process involves evacuating the old refrigerant, flushing the system, and then charging it with R – 410A. Industry – standard approaches should be followed for a successful replacement. Detailed in our [R‑410A vs R‑22 replacement] section.

R – 410A vs R – 454B: Which is a better refrigerant for heat pumps?

R – 410A was a popular replacement for R – 22, but it has a high GWP of 2088. R – 454B, on the other hand, has a much lower GWP of 466. Clinical trials suggest R – 454B offers similar or better efficiency in some cases. Unlike R – 410A, R – 454B is more eco – friendly. Results may vary depending on the specific system and climate.